1. Advanced technology: the line adopts continuous coil production after cold bending to determine the precision of the long cutting parts forming shape rules length accurate consistency.Good appearance and high strength of molding workpiece.

2. High productivity: this line only needs 2-3 people to operate, with simple operation and low labor intensity. The production speed of this line is adjustable from 10 to 15 meters per minute, and the normal operation speed is 8 to 15 meters per minute.

3. High reliability: the main components of the hydraulic, pneumatic and electrical systems of this line all adopt imported high-quality components with stable performance and high reliability materials applicable to high technical parameters.

company-profile-module $!{companyProfile}

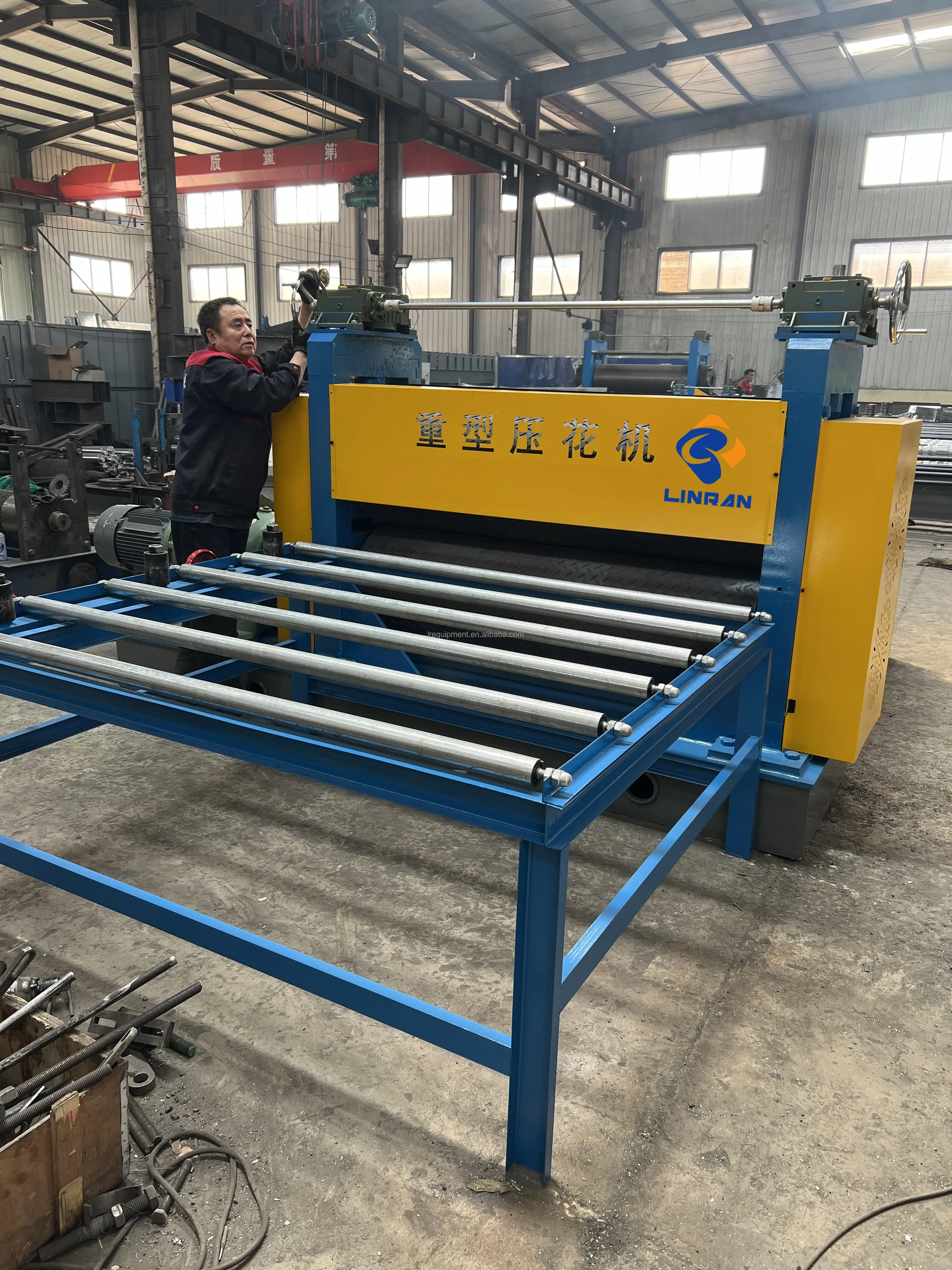

Roll Embossed Automatic Stamped Metal Steel Sheet Embossing Making Equipment

Popular

Popular in

-

1 - 1 Sets

$15,250.00

-

>=2 Sets

$7,280.00

- Model Number:

- Embossing machine

- Production Capacity:

- 15 m/min

- Power:

- 10KW

- Inventory Status:

-

In Stock

- Lead time:

-

Quantity(Sets) 1 - 1 2 - 2 3 - 3 >3 Lead time (days) 40 38 35 Negotiable

- Customization

-

Flower type (Min. Order: 1 Sets)Voltage (Min. Order: 1 Sets)

More

Thickness (Min. Order: 1 Sets) Less

Product details

Company profile

Overview

Essential details

- Type:

-

Embossing machine, Automatic

- Tile Type:

-

Steel

- Use:

-

FLOOR

- Place of Origin:

-

Henan, China

- Brand Name:

-

LINRAN

- Voltage:

-

220/380/415

- Dimension(L*W*H):

-

3000 * 1200* 1400

- Weight:

-

3000 kg

- Warranty:

-

3 years

- Key Selling Points:

-

Automatic

- Rolling thinckness:

-

0.3-1mm

- Feeding width:

-

1000mm

- Machinery Test Report:

-

Not Available

- Video outgoing-inspection:

-

Provided

- Core Components:

-

Motor, Bearing, Gear, Pump, PLC

- Product name:

-

Tile embossing machine

- Usage:

-

Building

- Cutting blade material:

-

Cr12 Frequency Quenching

- Shaft material:

-

45# Steel Outer Diameter: 80mm

- Raw material:

-

PPGI PPGL GI GL

- Control system:

-

PLC(detla) System

- Main frame:

-

Steel Plate Welded

- Function:

-

Roof Usage

- Thickness:

-

0.3--1.0mm

Packaging & delivery

- Lead time :

-

Quantity(Sets) 1 - 1 2 - 2 3 - 3 >3 Lead time (days) 40 38 35

Online Customization

Video Description

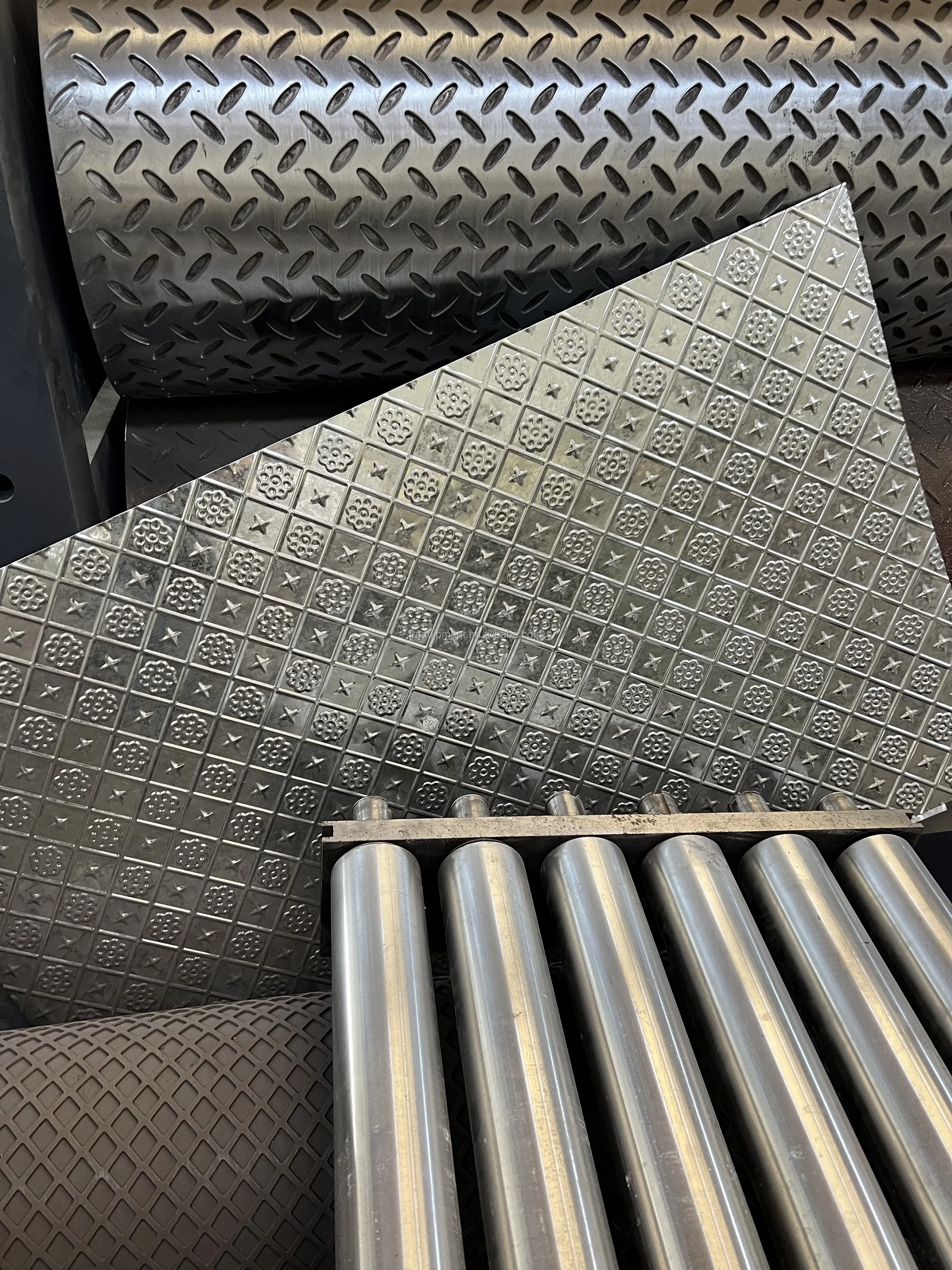

Roll Embossed Automatic Stamped Metal Steel Sheet Embossing Making Equipment

Profile drawing

Processing line

Roll Embossed Automatic Stamped Metal Steel Sheet Embossing Making Equipment Processing Line:

5T or 8T hydraulic decoiling machine(with car loading)--Embossing machine

Manufacturing Technique

Roll Embossed Automatic Stamped Metal Steel Sheet Embossing Making Equipment

1 | Automatic Grade | Automatic | ||||

2 | Production Capacity | 8-15M/MIN | ||||

3 | Power | 10KW | ||||

4 | Dimension(L*W*H) | 3000x1300x1200mm | ||||

5 | Weight | 5000kg | ||||

6 | Voltage | 380V 50HZ OR AS CUSTOMER REQUIRED | ||||

Configuration

Roll Embossed Automatic Stamped Metal Steel Sheet Embossing Making Equipment

Decoiler

Hydraulic decoiling machine--5T/8T/10T can be choosed.

Also, electric decoiler be matched--3T or 5T as per client's request.

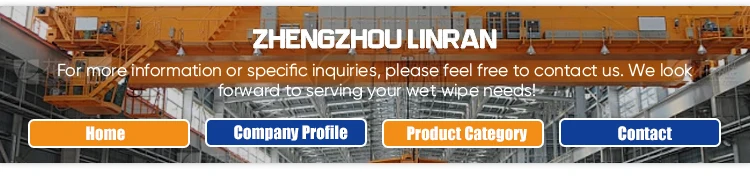

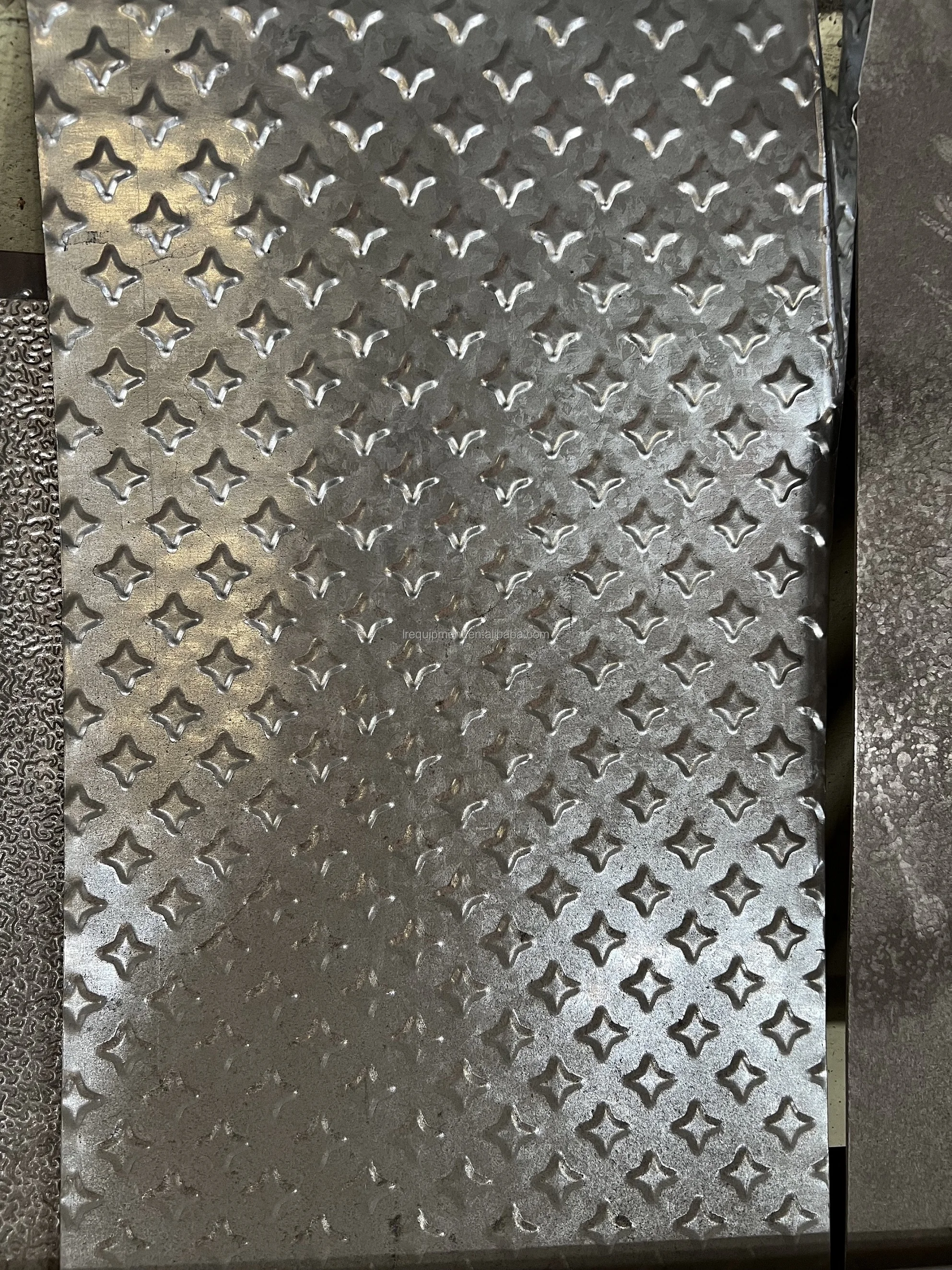

Embossing

Roller size:Φ230×1500mm

Roller material:Heat treatment of bearing steel

Embossing adjustment:reducer pressurization

Transmission way:Gear transmission

Material of embossing roller:60CrMnMo

Hardness of embossing roller surface:HRC 60-63

Depth of hardness surface:5-10mm

Suit for embossing steel:thickness 0.8mm SS,width within:1250mm

Bearing:24044 type ø220 ø340 118mm 4 pieces

Bearing box:520*480*160mm 4 pieces

Driving: 30kw SIEMENS 4P AC motor, inverter control, reducer: BWD7-59-30kw 4P

Pressure mode:hydraulic pressure oil cylinder ø320 2pcs

With hydraulic station:Closed shields, safety devices

Roller material:Heat treatment of bearing steel

Embossing adjustment:reducer pressurization

Transmission way:Gear transmission

Material of embossing roller:60CrMnMo

Hardness of embossing roller surface:HRC 60-63

Depth of hardness surface:5-10mm

Suit for embossing steel:thickness 0.8mm SS,width within:1250mm

Bearing:24044 type ø220 ø340 118mm 4 pieces

Bearing box:520*480*160mm 4 pieces

Driving: 30kw SIEMENS 4P AC motor, inverter control, reducer: BWD7-59-30kw 4P

Pressure mode:hydraulic pressure oil cylinder ø320 2pcs

With hydraulic station:Closed shields, safety devices

Recommend Products

Our Advantages

Packing & Delivery

1.Packing:

1)Machine is nude loaded in the container

2)The electric controlling box is packed by protect film

3)All the spare parts are put in the wooden box

2.Delivery:

1)Sea shipping

2)Air shipping for sampling

3)Train shipping for landlocked countries serviced by CRExpress Europeblock train

1)Machine is nude loaded in the container

2)The electric controlling box is packed by protect film

3)All the spare parts are put in the wooden box

2.Delivery:

1)Sea shipping

2)Air shipping for sampling

3)Train shipping for landlocked countries serviced by CRExpress Europeblock train

Zhengzhou Linran Equipment Co., Ltd. established in the year 2003, manufacturing and exporting Metal Roll Forming Machines.All efforts are devoted to the research and development of how to provide customers with high-quality and durable molding machines.Our main product Metal Roll Forming Machine, such as C/Z Purlin Roll Forming Machine, Cold Sheet Forming Machine,Metal Deck Roll Forming Machine,Omega profile roll forming machine, Guardrail roll forming machine, Downspout roll forming machine, Rain gutter roll forming machine etc. have been exported more than 100countries like USA, Mexico, Canada, Spain, Russia, Singapore, Thailand, India etc.Our company has successfully established and passed the ISO9001 quality insurance system, also had been approved with CE certificate.For our roll former, 36 month free warranty, and our company promises that we will provide product service life maintenance service.

We have been exported our products to many countries and regions, all over the world, especially in Burma,

Kenya, Zambia, Ethiopia, SaudiArabia, Vietnam, Malaysia, Indonesia, Singapore.Our products have own praises from all over customers worldwide.

We have been exported our products to many countries and regions, all over the world, especially in Burma,

Kenya, Zambia, Ethiopia, SaudiArabia, Vietnam, Malaysia, Indonesia, Singapore.Our products have own praises from all over customers worldwide.

Our company occupies an area over 86000m² acres and has standardized industrial workshop 66000m²,A variety of

large and medium-sized processing equipment more than 100 sets, advanced processing technology.It is a green construction equipment manufacturing base.

large and medium-sized processing equipment more than 100 sets, advanced processing technology.It is a green construction equipment manufacturing base.

Why Choose Us

Why choose LINRAN

1. Unique coil processing solutions for metalworking?

ZHENGZHOU LINRAN EQUIPMENT is aimed at providing our customers with the best quality metal rolling automation solutions and after-sales service.

2. Equipment research and developing.

Our company commits to providing customized coil processing solutions according to each customer's specific metalworking process.

With an experienced technical team and continuous research investment, we are capable to offer coil handling solutions that meet higher international standards.

3. Manufacturing quality control.

With precision machine tools and skilled workers, from spare parts preparation to equipment assembly, our machine can offer real-time manufacturing updates for our valued customers.

From raw material control, spare parts inspection, and machine assembly, our factory implements a strict quality control process. We commit to offering coil performance. Our work is just for making sure all the products of machines are qualified.

ZHENGZHOU LINRAN EQUIPMENT is aimed at providing our customers with the best quality metal rolling automation solutions and after-sales service.

2. Equipment research and developing.

Our company commits to providing customized coil processing solutions according to each customer's specific metalworking process.

With an experienced technical team and continuous research investment, we are capable to offer coil handling solutions that meet higher international standards.

3. Manufacturing quality control.

With precision machine tools and skilled workers, from spare parts preparation to equipment assembly, our machine can offer real-time manufacturing updates for our valued customers.

From raw material control, spare parts inspection, and machine assembly, our factory implements a strict quality control process. We commit to offering coil performance. Our work is just for making sure all the products of machines are qualified.

Service LINRAN offer

We establish whole heartedly a convenient and fast service ,and will "advance service","whole process service"and "life long service"throughout the whole process of cooperation.

✩Pre-sales

To receive technical advice from users,assist in engineering planning and demand analysis,and formulate a completeplant construction plan.

✩In-sales

We can send professional and technical personnel toguide the user construction on site,guide the installation and debugging of equipment,train production operators andequipment maintenance personnel,and provide free formularatio until the qualified product is produced.

✩After sales

The main machine warranty is one year,the equipment is maintained for life,and provide users with convenient after-sales service and product upgrade services in time.

To receive technical advice from users,assist in engineering planning and demand analysis,and formulate a completeplant construction plan.

✩In-sales

We can send professional and technical personnel toguide the user construction on site,guide the installation and debugging of equipment,train production operators andequipment maintenance personnel,and provide free formularatio until the qualified product is produced.

✩After sales

The main machine warranty is one year,the equipment is maintained for life,and provide users with convenient after-sales service and product upgrade services in time.

FAQ-LINRAN

1.How to maintain the machine?

Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.

2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. B: 2) Please visit company and test machine if convenient.

Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.

2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. B: 2) Please visit company and test machine if convenient.

You May Like

Not exactly what you want? 1 request, multiple quotations Get Quotations Now >>

You May Like

For more detailed information including pricing, customization, and shipping:

Contact supplier

Call Us

Call Us

Call Us

Call Us

Trading Company

|

≤1h

Response Time

The average amount of time supplier took to respond to every buyer’s first message over the past 30 days.

|

|

|

40,000+ for 1 Transactions

The supplier’s transactions conducted via Chovm.com in the past 6 months.

|

|

| On-time delivery rate |